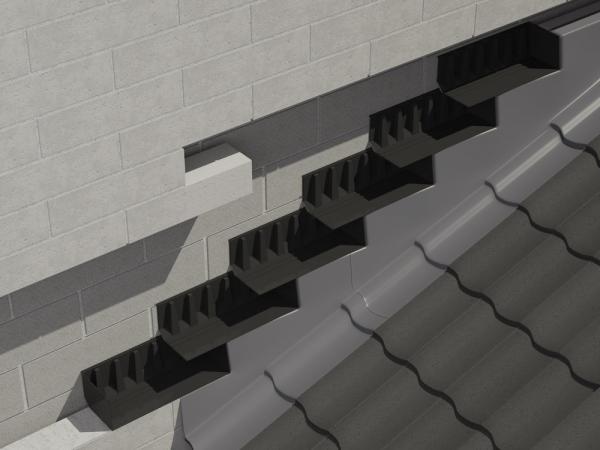

Blockwork Corner Starter Tray LH

BBA approved pre-formed stepped cavity tray system for installation at the abutment of a pitched roof with an external cavity wall supplied without integral lead flashing.

For external walls not exceeding 150mm thickness and built from blockwork or stone with regular course heights, including mortar, of approximately 225mm and clear cavity widths of between 50mm and 125mm

cavity trays to suit clear cavity widths of 126mm + are available to order.

Choice of 2 cavity tray lengths to suit specific roof pitches with a variety of base widths for different wall thicknesses and clear cavity width combinations.

Also available fitted with integral lead flashings or with supplied with mortar barrier strips to aid the installation of post fitted lead flashing.

In comparison to alternative on-site DPC fabricated methods; preformed cavity trays present many features and benefits including reliability, speed of installation, reduced cold bridging opportunity and site waste.

Features & Benefits

Robust and reliable DPC method

Permanent stopend protects the perp joint and cuts out water backtracking along the blockwork

Reduces cold bridging opportunities

150mm high back self-supporting upstand

Built into the outer wall leaf only allowing both internal and external leafs to be built independently

Quicker and simpler to install compared to alternative DPC methods

Won’t degrade over time

Doesn’t change or distort under high loads

Isn’t affected by high or low temperatures

Won’t drop and collapse into the cavity

Doesn’t usually require cutting into insulation

Accommodates lead flashing to be securely attached

Can be prepared in convenient plot specific order consignments

Reduces site material waste

Applications

Preformed stepped cavity trays ‘step up’ the external cavity wall in order to follow the abutment of a pitched/gabled roof such as:

attached garages

conservatories and extensions

porches and bay windows

attached buildings with different roof lines.

Choice of 2 cavity tray lengths:

625mm for roof pitches of 25° or above

1250mm for roof pitches of 12.5-22.5°.

For external cavity walls built from blockwork or stone:

with regular course heights of 225mm inc. mortar

not exceeding 150mm thickness

with clear cavity widths of between 50-125mm

made to measure design and manufacturing service available for non-standard projects.

Technical Information

With pre-formed cavity trays it’s not strictly necessary for the tray to span all the way across the cavity (except projects in severe weather exposure areas).

As long as the cavity tray stands back from the rear face of the masonry and projects back into the cavity far enough to intercept drips falling from the wall ties, then it will perform effectively.

If installing cavity trays with a partial fill cavity insulation, please deduct the insulation material depth to calculate the available ‘clear cavity width’.

The different types cavity trays in a stepped system:

Intermediate cavity tray - suits all cavity options and forms the main tray run with one tray on each course of brickwork running the full length of the abutting roof slope

Stopend starter cavity tray - this is the first component to be installed and fitted at the lowest point on a standard abutment. It collects the water that is gathered by the rest of the system and discharges it from the wall through a weep hole or vent

Corner starter cavity tray -this has the same function as a stopend starter tray, but it is used where the abutting roof comes up to, or beyond, the corner of the main building. It is designed to return around the corner of the building to provide complete protection from water ingress

Ridge cavity tray - used where a right and left hand roof slope come together at an apex to straddle the top two intermediate trays

Weep holes and vents - cavity trays must be installed in conjunction with proprietary weep holes or vents to ensure that any water collected with the cavity tray system is discharged back out through the external wall leaf.

We strongly recommend the specification and installation of purpose made wall weep/weep vent products, such as Timloc’s 1143 wall weep vent or TW1 concealed wall weep ranges to guarantee an accurate fit with the tray and a reliable discharge of water.