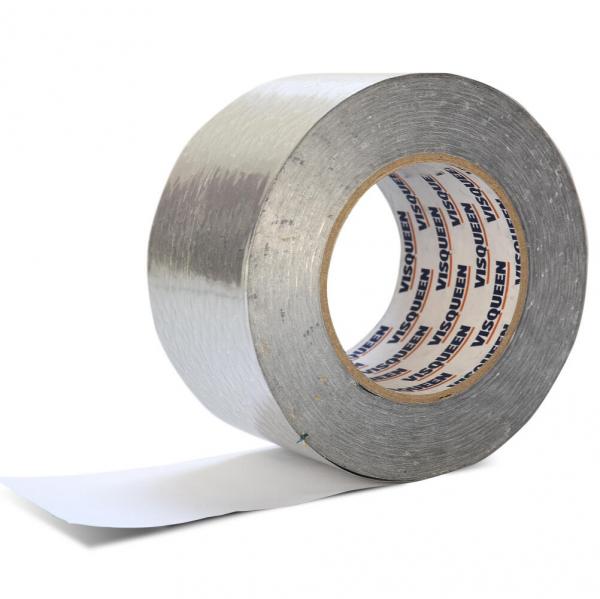

Gas Resistant Foil Backed Tape 75mm x 50m

Visqueen Gas Resistant Foil Lap Tape, 75mm x 50m

Product description

Visqueen Gas Resistant (GR) Foil Lap Tape is an overlap tape which has a solvent acrylic adhesive with a composite aluminium/

PET carrier therefore it is resistant to alkaline which is present in cement and concrete. The tape also has a release flm.

The product is supplied in roll format 75mm x 50m.

To be used in conjunction with Visqueen Pro Double Sided Jointing Tape 50mm x 10m.

Usage

Visqueen Gas Resistant Foil Lap Tape is used to bond lap joints on gas protection membranes. It can be used internally and

externally and is suitable in compressed load applications.

Features and benefts

BBA certifed jointing system - third party accreditation

Complies with BS 8485:2015 + A1:2019 - industry standard for methane and carbon dioxide protection

Good adhesion properties - provides an overlap seal to Visqueen gas protection membranes

Joint integrity - stops poured concrete entering the lap joint

Heath and Safety - seals the exposed lap from risk of installer accidents

Storage and handling

Store in warm, dry and clean environment in its current packaging. The tape should not be exposed to long periods of ultraviolet

light. In very cold weather, prior to use ensure that the material is stored in warm conditions above 5°C.

Preparation

Ensure all surfaces are clean and dry. The membrane joint surfaces should be dry and free from contamination such as dust or

sand. Ensure the surface and working area is not water logged. Avoid areas of unsupported jointing.

Installation

The membrane should be overlapped by at least 150mm, bonded with Visqueen Pro Double Sided Jointing Tape and sealed with

Visqueen Gas Resistant Foil Lap Tape.

When using the GR Foil Lap tape, apply the tape equidistant over the lap area of the laid sheet and the overlap adjoining

membrane. Apply pressure to the jointed area to ensure adhesion. Once the tape is applied, the completed lap should be well

rolled with frm pressure to ensure a complete seal joint has occurred, and continuity with the adjacent sheet has been achieved.

Usable temperature range

It is recommended that the system components should be used above 5°C.

Additional information

In demanding site conditions seal lap joints with Visqueen Ultimate GR Lap Tape.

Approvals and standards

Third party accreditation (BBA 13/5069)

Conforms to the specifcation requirements of BS 8485:2015 + A1:2019

Quality Management System ISO 9001:2015

Occupational Health and Safety System ISO 18001:2007

Environmental Management System ISO 14001:2015