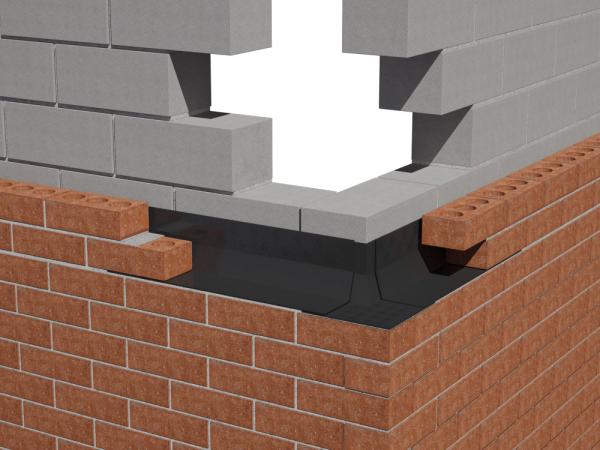

System 2000 Horizontal Internal Corner

Preformed horizontal cavity trays provide protection from water penetrating the external wall leaf of a cavity wall down through to the internal wall leaf in specific vulnerable areas across the building such as:

the abutment of a flat, lean to or mono-pitched roof

over concrete ring beams

over building components that can act as a through cavity carrier such as air bricks, meter boxes, ducts and cavity liners.

For external wall constructions not exceeding 102.5mm in thickness and clear cavity widths of between 50mm and 125mm:

trays to suit clear cavity widths of 126mm+ are available to order.

Available in two standard lengths:

880mm for general use

460mm to reduce waste when making up a run of cavity tray to the required length.

Features & Benefits

Tough and stable DPC method

Consistent protection across the project

Suitable for brick, block and stonework constructions

To fit clear cavity widths of between 50-125mm

Cold bridging opportunities reduced

Generally doesn’t require cutting into insulation

150mm high back upstand exceeds NHBC requirements

Allows inner and outer wall leafs to be built independently if required

Doesn’t degrade over time or under high loads

Isn’t affected by temperatures

Rigid construction that won’t collapse into cavity

Can be dispatched in convenient plot/area specific order consignments

Applications

External cavity walls abutting flat, lean to or mono pitched roofs such as:

attached outbuildings and garages

conservatory and extensions

porches and bay windows

attached buildings with different roof lines.

Over concrete ring beams or slabs and building components that can act as through cavity water carriers such as:

air bricks and cavity sleeves

ducts

meter boxes.

For external cavity walls built from standard brick, block and stonework:

not exceeding 102.5mm thickness

with clear cavity widths of between 50-125mm

trays to suit clear cavity widths of 126mm+ can be made to order - please contact us with your project details.

Technical Information

With pre-formed cavity trays it’s not strictly necessary for the tray to span all the way across the cavity (except projects in severe weather exposure areas).

As long as the cavity tray stands back from the rear face of the masonry and projects back into the cavity far enough to intercept drips falling from the wall ties, then it will perform effectively.

If installing cavity trays with a partial fill cavity insulation, please deduct the insulation material depth to calculate the available ‘clear cavity width’.

Stopends must be specified and installed at the start and finish of the System 2000 cavity tray run to seal off the open ends and prevent water running back into the cavity.

Cavity trays work in conjunction with weep holes:

trays collect and retain water inside the cavity wall

weep holes discharge water back out through the external cavity wall leaf.

Weep holes must be provided every 900mm along the run to comply with Building Regulation requirements.

We recommend that purpose made weep holes/weep vents are installed, such as Timloc’s:

wall weep vents - 1143 range

concealed wall weeps - TW1 range.