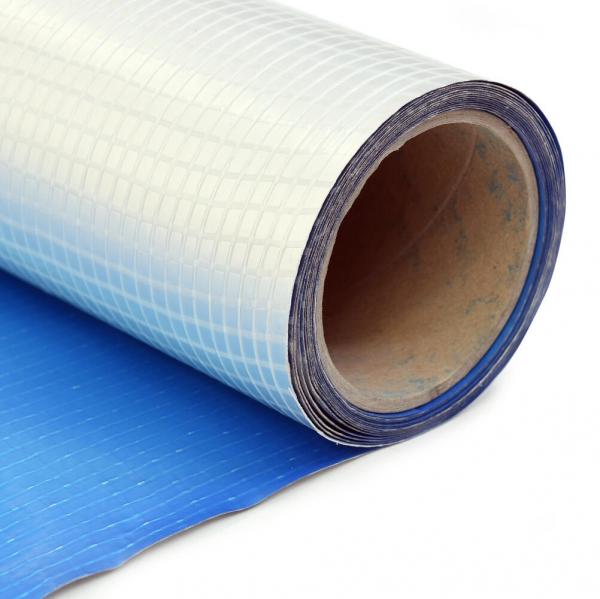

Visqueen Gas Barrier 2m x 50m

Visqueen Gas Barrier

Product description

Visqueen Gas Barrier is a multi-layer reinforced polyethylene gas barrier with a 20 micron aluminium foil. The barrier is coloured blue on the upper surface and silver on the reverse. The product is supplied in single wound rolls (not folded), 2m x 50m.

Usage

Visqueen Gas Barrier is suitable for use in all types of buildings to prevent the ingress of harmful levels of ground gases, methane, carbon dioxide and radon.

The barrier can be positioned above or below a solid concrete ground floor slab or above a precast suspended segmental ground floor system, e.g. beam and block floor.

The barrier can also be used as a high performance radon membrane and/or damp proof membrane.

The product is not intended for use where there is a risk of hydrostatic pressure.

Storage and handling

Visqueen Gas Barrier should be stored horizontally, under cover in its original packaging.

Care should be taken when handling the product in line with current manual handling regulations.

Preparation

Visqueen Gas Barrier should be installed on a smooth continuous surface e.g. grouted beam and block floor, a compacted blinding layer e.g. 50mm thick sand blinding, or smooth concrete blinding. The substrate should be free from irregularities such as voids or protrusions.

The barrier can be cut with a sharp retractable safety knife or robust scissors.

Installation

Visqueen Gas Barrier should be loose laid on the substrate with the blue side up so as to avoid sunlight glare.

The barrier should be clean and dry at the time of jointing. It should be overlapped by at least 150mm, bonded with Visqueen Pro Double Sided Jointing Tape and sealed with Visqueen Foil Lap Tape. In demanding site conditions seal lap joints with Visqueen Ultimate GR Lap Tape. Alternatively lap joints can be heat welded to achieve an effective seal. Welded lap joints can be less than 150mm provided the joint integrity is not compromised.

Airtight seals should be formed around all service entry points. Visqueen Preformed Top Hat Units should be used for sealing service entry pipes. The base of the top hat and the upstand should be bonded using Visqueen Pro Double Sided Jointing Tape and sealed with Visqueen Foil Lap Tape. The upstand should be secured with the supplied jubilee clip.

Forming an effective barrier to gases may give rise to complex three-dimensional detailing where, it is recommended Visqueen Preformed Units are used e.g. corners. Alternatively Visqueen Pro Detailing Strip can be used to seal awkward junctions.

If the barrier is punctured or perforated a patch of the same material should be lapped at least 150mm beyond the limits of the puncture and bonded with Visqueen Pro Double Sided Jointing Tape and sealed with Visqueen Foil Lap Tape. Alternatively a patch can be formed using Visqueen Pro Detailing Strip and lapped at least 150mm beyond the extents of the puncture.

The barrier should be covered by a protective layer as soon as possible after installation to prevent damage e.g. from following trades. Care should be taken to ensure that the membrane is not punctured, stretched or displaced when applying a screed or final floor covering. A minimum thickness of 50mm screed is recommended. When reinforced concrete is to be laid over the barrier the wire reinforcements and spacers must be prevented from puncturing the barrier. Where there is a high risk of potential damage, the barrier should be covered with Visqueen TreadGuard protection, screed, or other approved protection material

before positioning the reinforcement.

Usable temperature range

It is recommended that Visqueen Gas Barrier and all associated system components should not be installed below 5°C.

Additional information

When used in accordance BS8485:2015 + A1:2019 a subfloor ventilation system or pressure relief maybe required.

Where hydrocarbon or VOC contamination is present use Visqueen Ultimate VOC or HC Blok gas protection systems.

To assist build sequencing, Visqueen GR DPC is available for gas protection through the wall constructions. For suspended beam and block floor detailing see GB-01

Visqueen Preformed Top Hat Units should be used at service pipe penetrations see GB-51

For internal and external corners Visqueen Ultimate Preformed Units should be used see PFU-553

To seal around steel columns use Visqueen Pro Detailing Strip see GB-52

System components

VisqueenPro Double Sided Jointing Tape, 50mm x 10m

Visqueen Gas Resistant Foil Lap Tape, 75mm x 50m

Visqueen Ultimate GR Lap Tape, 150mm x 10m

Visqueen Ultimate Top Hat Units

Visqueen Preformed Units

VisqueenPro Detailing Strip, 300mm x 10m, 500mm x 10m

Visqueen TreadGUARD 300, 2m x 75m

Visqueen TreadGUARD 1500, 1m x 2m

Features and benefits

- BBA certified - third party accreditation

- Complies with BS 8485:2015 + A1:2019 - industry standard for methane and carbon dioxide protection

- Flexible - easy to detail and install on site

- Multi functional - also acts as a radon and damp proof membrane

- Dual jointing methods - lap joints can be taped or heat welded

Approvals and standards

- Third party accreditation (BBA 13/5069)

- Conforms to the specification requirements of BS 8485:2015 + A1:2019

- Suitable for all Characteristic Gas Situation (CS) ground gas regimes

- Conforms to the specification requirements of NHBC Amber 1 and Amber 2 applications

- Conforms to the specification requirements of BR 211:2015

- CE Mark EN 13967:2017

- Quality Management System ISO 9001:2015

- Occupational Health and Safety System ISO 18001:2007

- Environmental Management System ISO 14001:2015