100mm Thermo-loc 30 Min FR Cavity Closer

Thermo-loc FR30

Use

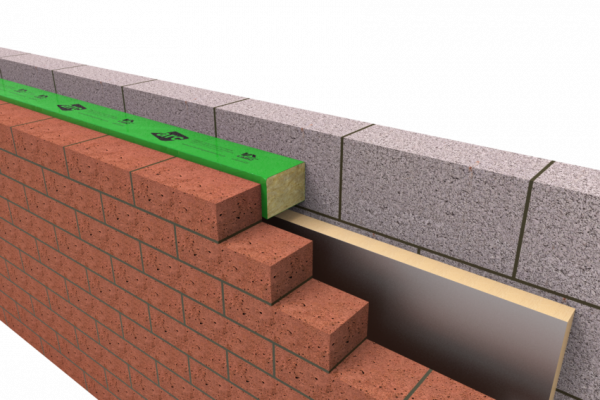

• To close the cavity at external doors, window jambs and sills.

• To provide thermal insulation and prevent ‘cold bridging’.

• To provide a DPC at external doors, window jambs or sills.

• 30 minutes fire rating and minimum 15 minutes insulation.

• Suitable for cavities up to 300mm.

• Suitable for timber and masonry walls.

Features and benefits

• Provides an effective DPC and thermal barrier between frame, inner and outer wall leaf.

• Thermal conductivity of 0.036W/mK.

• Exceeds the minimum thermal resistance path of 0.45m2K/W stipulated in ‘Part L’ accredited construction details.

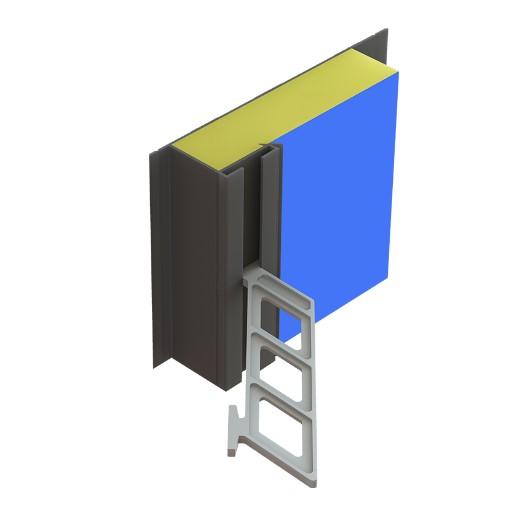

• Rigid profile extrusion allows both first and second fix.

• Suitable for all frame and sill positions (see fig.1).

• Durable and resistant to decay.

• Insulation option to suit your requirements both thermal and fire rated.

• Global warming potential of zero

• Ozone depletion potential of zero

• Available fully rebated - Check reveal (single flange)

Installation advice

• Can be used in both first and second fix applications.

• Cut the cavity closer into required lengths allowing the jamb section to overlap the sill section and to butt the underside of the lintel

• In first fix application the cavity barrier should be nailed to the jamb/sill of the door or window frame and the whole assembly built in as

work proceeds. Alternatively the barrier can be built in sections using fixing ties as work proceeds.

• For second fix applications, the cavity closer is pushed into the open cavity after building work is complete. The compressible nature of

the exposed insulation material is used to create a friction fit in the cavity, secure nail fixing is required.

• Joining ‘off cut’ sections should not be carried out for the FR range.

How to order

• Establish the cavity width and select the correct cavity closer width, or the next size up to ensure the cavity can be closed.

• In jamb and sill applications, first estimate the total length of cavity barrier required, then order the correct number of individual 2.4

metre lengths so no joint pieces.

• Fixing ties are available for secure fixing if required (particular attention around door openings). Allow for ties fitted at 450mm centres.

Technical considerations

• BRE Document ‘Thermal insulation: avoiding risks’ and Robust Details stipulate: “When a window or door frame is set back behind the inner

face of a dense outer masonry leaf, it should overlap an insulated closer by a minimum of 30mm for BRE exposure zones Sheltered to

Severe; but fully rebated (check reveals for zones Very Severe’’ (see Fig.2).

• With reference to insulation, the products in this range do not use, contain or produce Urea Formaldehyde, CFC’s or indeed any of the

so called soft CFC’s, ie. HCFC’s & HFA’s. They conform to the Montreal Protocol and have an ozone depletion potential of zero and global

warming potential of zero.

Material

• Rigid profile extruded in white UPVC

• Supplied in 2.4 metre lengths

• Standard cavity options available 50mm - 300mm

• Rockfibre mineral wool (FR) insulation 0.036W/mk

Quality

• Independently tested by Warrington Fire

• LABC Registered Detail

• Satisfies NHBC Standards

• Manufactured to BS EN ISO 9001 and BS EN ISO 14001

• Complies with Building Regulation Approved Documents C, B, L1 & L2

• Complies with ‘Part L’ accredited construction details

• Complies with the Scottish Building Standards ‘Technical handbook’

• Satisfies BRE document ‘Thermal insulation: avoiding risks’

• Meets all relevant British Standards